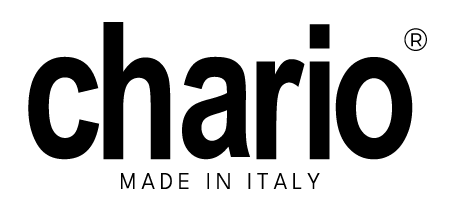

AVIATOR

BALBO

3 way Center Channel

The Aviator line center speaker has been created to be a simple, elegant, and performing solution for the home systems. Versatile and powerful, Balbo speaker is able to perform the thumping bass of a movie, or the pristine mids and highs of a female vocalist. Born as a center speaker Balbo grant all the performances usually provided by a 3 way speaker, rising the level of your system and increasing the listening experience

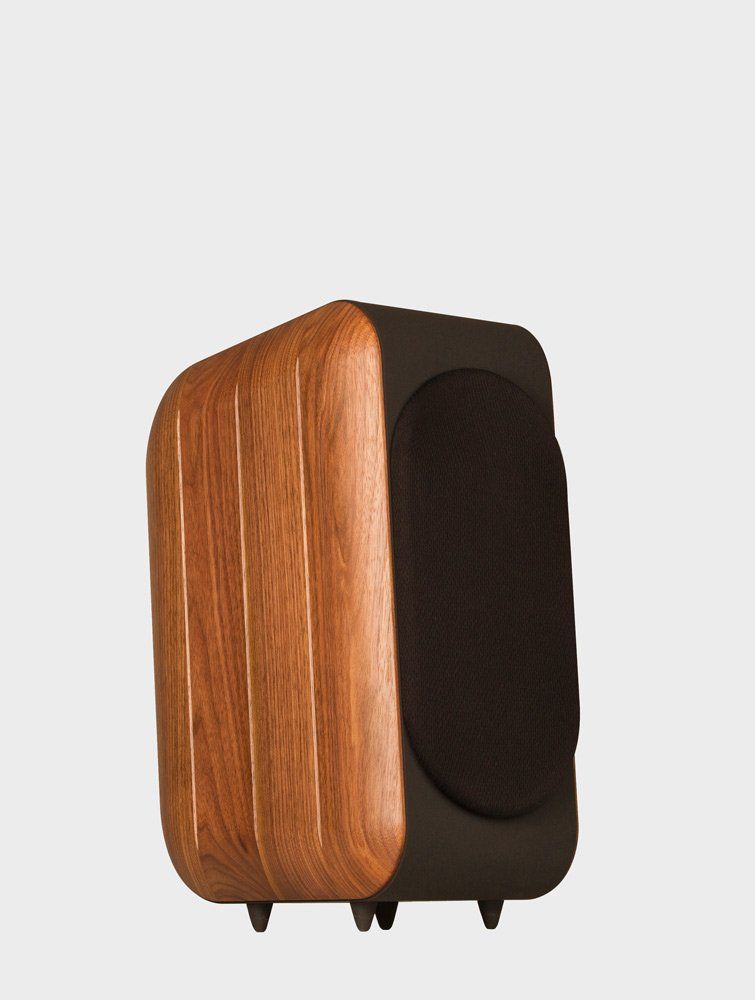

Our Wood

Aviator Balbo

The creation of a Chario piece of furniture begins with the choice of wood, strictly of Italian origin, and found in the numerous national walnut plantations in the north-eastern part of Italy.

Once the batch of trees most suitable for thickness and age has been chosen, we proceed with cutting to reduce the plant to a series of boards, easier to work with.

The boards thus obtained are then left to dry for at least six months, the first three of which in the open air. The humidity of the wood is measured every two weeks until the correct percentage of internal humidity is reached, which is essential to avoid abnormal behavior of the wood after processing.

The climate is a fundamental factor in this part of the process, an air humidity that is too high or too low, rains, snow, heat are all determining factors in the extension or reduction of the drying process.

Once the correct degree of internal humidity has been reached, the wood is cut into slats, maintaining the original coupling as well as that obtained by cutting into boards. The staves are then worked with a particular interlocking method that stabilizes and joins them permanently.

The minimum age of the plants chosen for cutting must be 20 years, this to obtain mature wood and therefore suitable for processing and above all to ensure environmental sustainability by giving time to the new plants to grow adequately and therefore to replace in number and quality those previously cut.

We are proud to state that the building process of the Chario diffuser you have today, of which the growth of the plant is a part, started 20 years ago